Showing 81 through 100 out of 130 articles containing "drill press table"

Jigs and Accessories

…tions of the screw holes. miter gauge for 45' and drill pilot holes. Then // // \ F0R90*CUTS miter cuts. screw the clamp… push straight ahead and press the work-piece down (to prevent chattering). No. 1 ShopNotes JIGS AND ACCESSORIES Table Saw Jointing Converting your fable…Read More

Adjustable Stop Block

… tune or "micro-adjust" their position. • It Block Both blocks attach to the router table fence with T-slot nuts and threaded knobs, see photo. Note: Although this stop block …you're going to clamp the stop block to your fence, don't drill the mounting holes. chamfer EDGES. Before you drill holes to mount the threaded rod, rout a chamfer on all …Read More

Indexing Jig

…with two "flats" on each side of the nut. These flats press up against the walls of the groove in the sliding … brad point bit in the end of the slot and made a mark.) Now drill a hole to fit the insert and thread it in the base…over the hole in your router table, see Fig. lib. Now with the jig clamped in place, drill •Vifi'-dia. holes up through …Read More

Tool Chest

…. All you have to do is press it down, pivot the splitter toward the back, and slip it right off. As you can see below, I drilled a hole in my insert plate so… since saws vary, you need to be sure to order the correct model for your table saw. Excalibur carries a Merlin splitter to fit almost a dozen contractor and cabinet saw models. For…Read More

Box Joint Jig

… is clamped to the drill press table so the upright extends over the edge. Then, with the work clamped to the -upright, loosen the table and swing the workpiece under the bit. NOTE: JIG MADE FROM 3/4"-THICK STOCK A vertical drilling jig holds long ivorkpieces securely in place when drilling holes …Read More

Shop Solutions

… ANGLED HOLES n Drilling an angled hole isn’t a tough task. Just tilt the drill press table to the desired angle and drill the hole. But resetting the table to a position that’s square to the bit can take some time. To get around this, I use an angled platform that clamps to the table of my drill press…Read More

Shop Short Cuts

…drilling in aluminum. a lip that holds the blank down tight against the base. The large base makes it easy to secure the jig to your drill press table for safe and trouble-free drilling. To make the clamp blocks, start with a long workpiece. I set my table saw up to cut a …Read More

Cordless Tool Station

…nal size, you can drill the holes to fit your chucks. To position the drills for easy access, I drilled these holes at a…DRILL PRESS TABLE 20˚, THEN USE SQUARE TO ALIGN TO AUXILIARY TABLE b. CLEAT NOTE: DRILL TOP STARTER HOLE WITH !/8"-DIA. BIT AUXILIARY TABLE a. TOP SECOND: DRILL STARTER HOLE WITH !/8"-DIA. BIT (DETAIL ‘a’) AUX. TABLE b. DRILL…Read More

Shop Short Cuts

…Drilling Drilling the angled holes for the dowels on the accessory clamp racks (page 21) is a simple task with this shop-made jig. It’s quick to build and easily clamps to your drill press table… TAPE NOTE: GUIDE STRIPS ARE MADE FROM !/4" HARDBOARD AND #/4" PLYWOOD 1 FIRST: DRILL STARTER HOLES WITH TAPE ON HOLE SAW (DETAIL ‘a’) 2 NOTE: ROUT …Read More

Readers Tips

…it could be used in the shop. One application I came up with is the drill press table you see in %/16"-18 STAR KNOB w/ %/16" FLAT WASHER FENCE BACK IS #/4" MDF 3!/2 2#/4 2… provides a lot of flexibility for installing hold-downs and a fence. After mounting the table to your drill press, you can start on the fence. I cut the fence face from the …Read More

Readers' Tips

…one side of the drill press table to make room for a dust port on the bottom. T-nuts and studded knobs attach the table to the drill press. Leo Smith Beaverton,…(3" x 18") !/4"-20 x 1!/2" STAR KNOB #/8 4 NOTE: LOCATE T-NUTS TO ALIGN WITH SLOTS IN DRILL PRESS TABLE (3" x 10!/2") SIDE 6 ShopNotes No. 122 Chamfer Jig I use dowels in a number …Read More

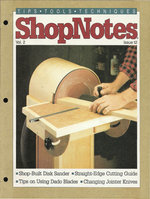

Disk Sander

… Fig. 2. These will be used later to attach the table to the case. To drill these holes straight, I used a jig on the drill press, see photo below. To complete the sides, I routed a… clearance between the sanding disk and the noteh in the adjustable table, see Fig. 16. Now you can drill shank holes centered in the slots in the motor's base. Then…Read More

Shop Solutions

… Box ■ I sand a lot of curved parts with a drum sander in the drill press. In the past, I've used a separate table for each different sized drum. To simplify things, I made a sanding box … my metal bench vise. To make it easy, I made them magnetic, see photo. Just drill several holes in the back of each pad and epoxy an inexpensive magnet in …Read More

Shop Solutions

…in ShopNotes No. 22 has helped me solve another problem — containing the dust the table saw produces. Along with four 1/4” Masonite panels cut to fit the sides of …a cutoff bolt with two washers, see detail ‘a’. Then, with the bolt chucked in the drill press, simply file a bevel and remove the burr. Doug Perlick Arden Hills, Minnesota ShopNotes …Read More

Mortising Machine

…a fence on the drill press to position each piece, see Fig. 10. DRILL HOLES. To form the pockets for the bushings, begin by drilling 3 "-dia. counterbores …10 No. 47 ShopNotes 21 F E A T U R E P R O J E C T Sliding Tables —11 This mortising table is designed with two sliding tables. A lower table moves from side to side, see Fig.…Read More

Readers' Tips

…a coved edge. Since I don’t own a shaper, I came up with another method using my table saw. The technique I use is to nibble away the waste around the raised… of Upper Saddle River, NJ fastens a piece of coiled copper wire to his drill press. { Before putting fasteners in his nail pouch, G r e g G o f o r t h of Ottawa, Ontario places them in…Read More

5-in-1 Router Base Plate System

…drill press rather than the router table. After locating the centerpoint of each plate, a 31/2"-dia. hole is drilled through the center of the lower plate, and a 3"-dia. hole is drilled…’s cut out on the 4 drill press, using a wing cutter. Start by carpet taping a hardboard blank down to a backer board that is clamped to your drill press, as shown …Read More

Thin-Stock Hold-Down

…SET IN COUNTERBORE C HOLD-DOWN BLOCK c. FRONT VIEW fence to the drill press, as in Figure 4. Then, you can drill the toilet bolt hole in the center of the block, …OF SUPPORT BLOCK FIRST: { Added Control. Using this jig with a zeroclearance insert on your table saw will give you greater control and accuracy when cutting thin laminates and veneers…Read More